Decarbonisation

Industry News

Mitsubishi Heavy Industries carbon capture tech selected for UK blue hydrogen plant

Mitsubishi Heavy Industries (MHI) will provide carbon dioxide (CO2) capture technology for the Hydrogen Production Plant 2 (HPP2) at the UK’s Stanlow Manufacturing Complex.

The plans have been solidified with a concluded license agreement between MHI and Kellogg Brown & Root (KBR), which is providing hydrogen production process technology and the front-end engineering design (FEED) for the project.

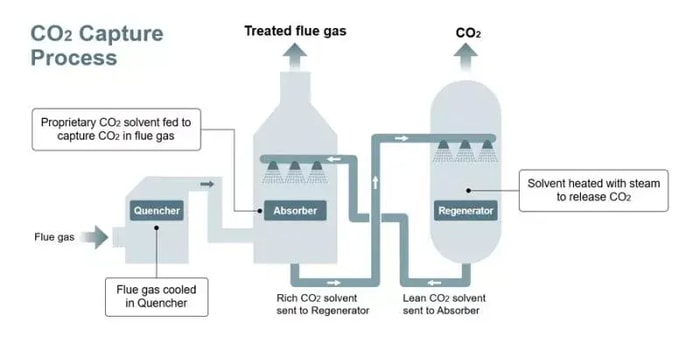

Under terms of the agreement, MHI will license its Advanced KM CDR Process™, a CO2 capture technology jointly developed with Kansai Electric Power. MHI will also provide the process design package for the new post-combustion CO2 capture plant.

The technology provided will support the project in becoming what is believed to be the UK’s largest-scale low-carbon hydrogen plant when it begins operation. HPP2 will have an annual hydrogen production capacity of nearly 230,000 tonnes.

© Mitsubishi Heavy Industries

HPP2 is a key pillar of the HyNet carbon capture, utilisation, and storage (CCUS) cluster. The captured CO2 will be permanently sequestered into depleted gas fields under the sea in Liverpool Bay.

Read more: UK govt reaffirms CCS commitment; announces milestone for HyNet NW Cluster

The UK Government’s Department for Energy Security and Net Zero (DESNZ) has selected two initial clusters – HyNet (where EET Hydrogen is leading the critical hydrogen production projects) and East Coast.

HPP2 augments the Hydrogen Production Plant 1 (HPP1) scheduled for construction as part of the large-scale low carbon hydrogen plant infrastructure planned by EET Hydrogen in the HyNet cluster.

ABOUT THE AUTHOR

Molly Burgess, Features Editor

How Can We Help You?

Please contact us regarding our services for a tailored

discussion of your needs.